““We had a concept that looked beautiful. But there were just so many barriers to making it real. SPARK was really good at identifying and surfacing key design and fit issues. They were fast, reliable, and clear, and we ended up with something we were very happy with.””

PARI Respiratory Equipment

Medical device company

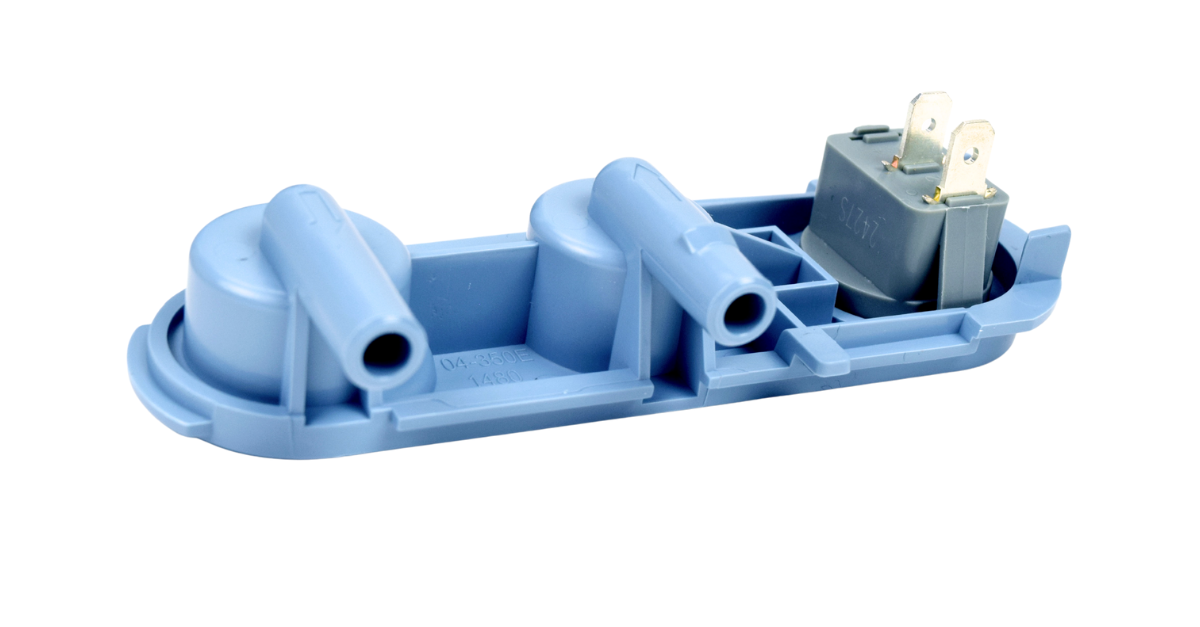

PARI Respiratory Equipment is a global leader in respiratory health, known for its high-quality nebulizers for the treatment of conditions like asthma, COPD, and cystic fibrosis. Their products are trusted by patients, providers, insurers, and clinicians around the world. When it came time to update one of their most important devices, the Vios nebulizer system, they turned to SPARK for help making their vision a (manufacturable) reality.

THE Challenge

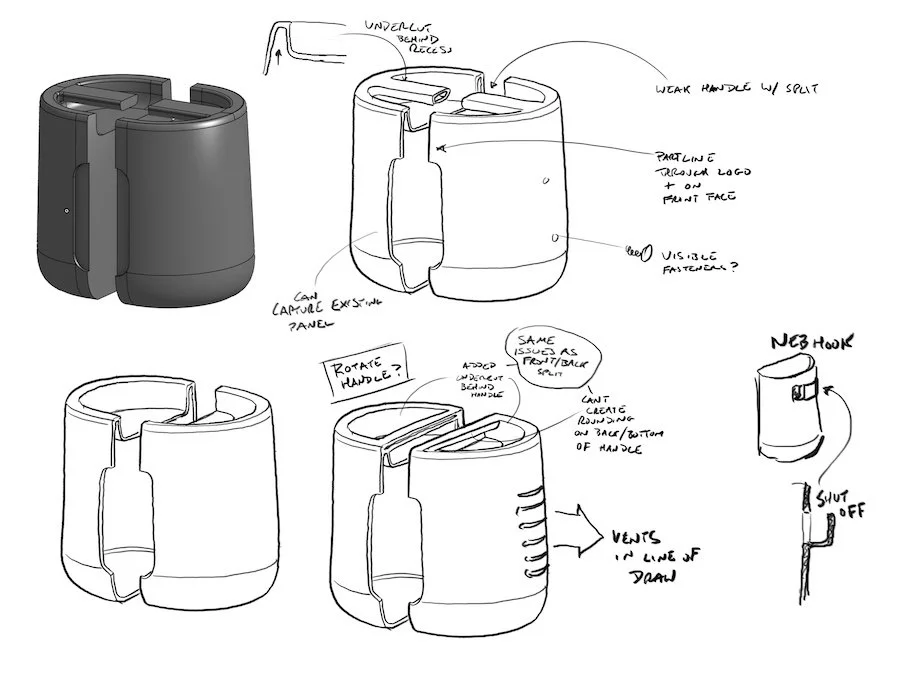

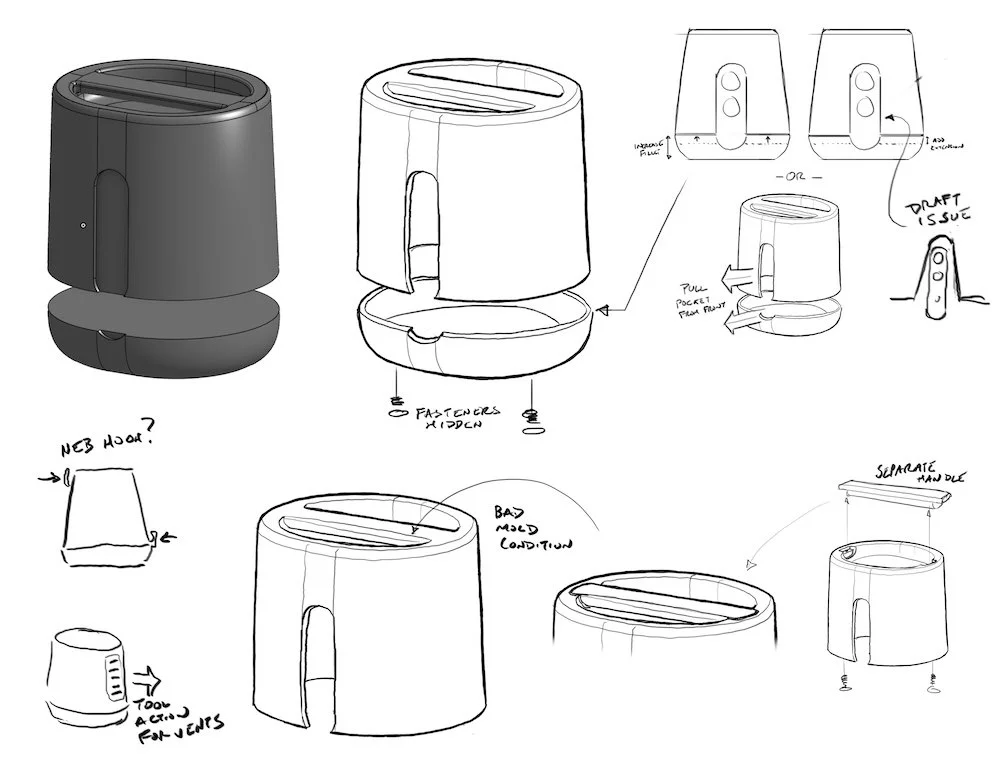

PARI’s Vios compressor, though widely used, hadn’t changed much since the early 2000s. By 2023, they were ready for a refresh. The company had initially engaged an industrial design firm to reimagine the look of the product, but the resulting concept, while sleek, would have been very difficult (and expensive) to manufacture.

With a small in-house engineering team, PARI needed an experienced partner to finalize the design, ensure manufacturability, and help keep the product on track.

THE SOLUTION

SPARK stepped in as a flexible design and engineering partner, helping PARI bridge the gap between industrial design and manufacturability. Working closely with PARI’s internal teams and external vendors, SPARK:

Integrated with the PARI team and stepped in as their outsourced engineering department, translating the initial product concept to a manufacture-ready design while adhering to strict constraints

Advocated for the PARI team and their product with the manufacturer, including negotiation of budget

Conducted prototype testing in alignment with medical device safety standards like IEC 60601 for Medical Electrical Equipment

Flagged key fit and design issues early, helping avoid delays later in the process

Handled vendor constraints and shifting requirements with flexibility, delivering quick turnarounds on multiple design iterations

Created tool ready 3D CAD and documentation to ensure readiness for production handoff

Provided design-for-manufacturing guidance and supported cross-team collaboration

The Impact

As a result of the collaboration, PARI was able to:

Maintain momentum on a priority product refresh and hit tight internal deadlines, even with an overloaded internal team

Redesign the compressor for improved usability, performance, and manufacturability

Up-skill new PARI team members across the full product development process

Continue building trust with partners and patients through a product that reflects both technical excellence and thoughtful design

Why it matters

Medical devices don’t just need to work, they need to inspire confidence, feel trustworthy in patients’ hands, and meet the rigorous demands of healthcare environments. This project shows how smart, responsive engineering and design collaboration can transform a beautiful concept into a production-ready product that better serves the people who rely on it.

““SPARK was just amazing to work with. Super fast, super responsive, and really flexible. It’s not easy to hit a moving target, but they kept showing up, stayed calm, and got it done.””