Core Capabilities

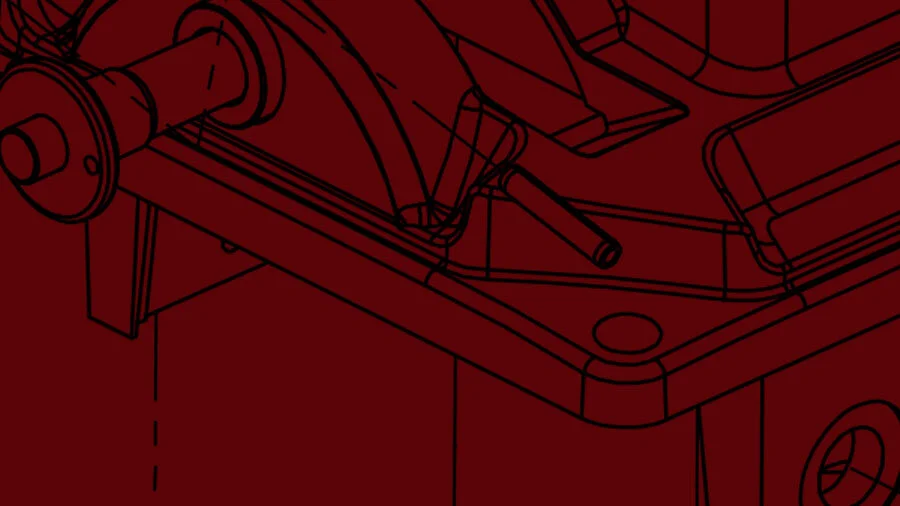

Our office is home to a collaborative team of product developers, whose foundation lies in mechanical engineering and industrial design, with a particular expertise in creating tool-ready designs. We have a broad range of in-house tools including 3D CAD software, 3D printers, and finite-element analysis (FEA), but if we can’t complete a task under our roof, we turn to our reliable network of vendors for processes like rapid prototyping or machining and fabrication. We also call upon design partners in the areas of electrical engineering, nonlinear and thermal analysis, and UX/UI. No matter how complex the problem, it’s likely SPARK can help.