Dometic Environmental

MARINE AIR CONDITIONING

Since 2006 Dometic Environmental has partnered with SPARK for specialized product development, starting with revamping their existing marine air-conditioning unit. The results have been continued market share domination for Dometic and multiple International Boatbuilders’ Exhibition (IBEX) Innovation Awards for their line of marine AC units.

“SPARK’s strengths are their versatility and ability to get the job done. If they do not have the expertise, they will find it and get the job done right. They are innovative, creative people that think outside the box.”

— Charlie Barefoot

(Global Product Development Director, Dometic Corp)

DRIVING INNOVATION

SPARK was first tasked with innovating around Dometic’s self-contained marine air conditioners, whose basic design had not changed for over a decade. Voice of the Customer research had identified the need for a dramatically improved install process and a method for reducing water (condensate) retention. Addressing these concerns and streamlining the design for production, SPARK’s work led to the award winning Vector Turbo.

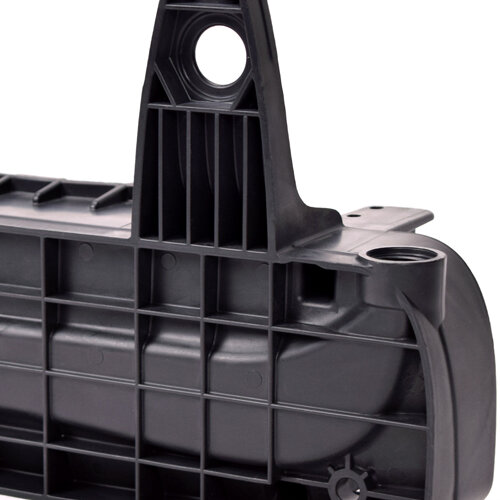

The Vector Turbo featured a molded plastic drain pan that allowed many of the individual components to be self-fixturing, greatly reducing part count and assembly time from prior models. The pans were molded with blowing agent so the impact resistant polypropylene would also be strong. As a major improvement to installation, SPARK also designed a blower ring that could be rotated nearly 360-degrees without increasing the overall unit height, so it could be installed in almost any orientation.

““This is a prime example of a manufacturer that listened to its customer feedback and retooled the product accordingly.””

SUCCESS BREEDS SUCCESS

After the success of the Vector Turbo, Dometic partnered again with SPARK to apply the same molded-chassis approach to their other popular marine units: the Turbovap DX, Emerald, and the Gold AU. Resulting in multiple IBEX innovation awards, SPARK’s designs helped to reduce standing water by as much as 85%, and by pairing the molded plastic drain pan with isolation mount points, unit vibration was reduced and installation was simplified for customers of all of these units.

One of the key improvements to Dometic’s AC units was SPARK’s innovative design for the inlet ring. The part was designed with an off-center rotation point, allowing installers to reorient the blower outlet as needed without increasing the unit’s height. Customers now had the flexibility to place the unit in whatever tight space their boat demanded.

SPARK’s molded-chassis drain pan was designed to allow 100% of water condensation to drain, which was not possible with prior models. Specially designed ribs were incorporated to control the flow of the water in the drain pan and prevent splashing caused by boat movement.

By updating the drain pans to a molded plastic design, SPARK was able to reduce standing water by 85%, unit height by 17%, and manufacturing and assembly space by 66%; all while improving overall unit performance and significantly reducing installation time.